Recently, the new material MOF developed by Japan has attracted worldwide attention.

This article explains MOF materials from the following aspects:

1. What is an organic metal frame structure?

Metal-organic framework (MOF) is a hot research topic in the field of new materials. Since the successful synthesis of MOF materials with stable pore structures by Yaghi’s group in the United States and Kitagawa’s group in Japan in 1990, a wide variety of MOF materials with high functionality, large porosity and specific surface area, adjustable pore size, biomimetic catalysis and biocompatibility have been emerging. At present, flexible, conductive and stable MOF materials with specific catalytic properties have been widely used in various research fields.

Translated with www.DeepL.com/Translator (free version)

2. Precautions for the preparation of MOF materials

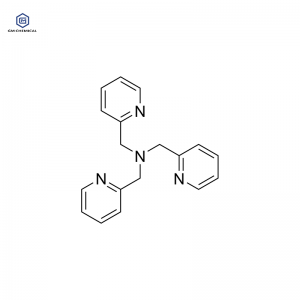

(1) Select appropriate organic ligands and metal elements, and synthesize selected MOF materials with different morphologies, sizes, selected functions and specific pore size distributions by adjusting the types of functional groups on the ligands and the types of metal salts.

(2) Clarify the synthesis mechanism of MOF, and obtain the designed crystal structure by controlling the synthesis conditions and selecting appropriate nucleation and growth methods.

3. The reasons for the multi-functional application of MOF materials

Metal and organic coordination form a specific framework structure. This structure not only has the activity of metals; it also obtains the flexibility of organic ligands, the selectivity of functional groups and other physical and chemical properties; and the special spatial structure formed by coordination. The perfect combination of these three powerful factors provides the basic conditions for the wide application of MOF materials.

4. The energy storage performance of the organometallic frame

The main problem in the application of MOF materials to the field of energy storage is that the conductivity and cycle life cannot meet the application requirements. Therefore, people use various types of MOF materials in supercapacitors and metal batteries to explore their electrochemical energy storage mechanism, the stability of electrode materials, charge transport pathways, mass transfer and electrochemical reactions. However, compared with MOF oxides and carbon material derivatives, the preparation methods of MOF thin film materials need to be further expanded; the research on conductive MOF is still in the initial stage, and the concentration, type and migration rate of carriers still need further research; The stability of the MOF electrode, the appropriate electrolyte, and the appropriate preparation method still need to be further improved.

5. Catalytic performance of organometallic framework

Although MOF contains catalytically active metals, the metal sites in MOF are usually combined with organic ligands, are not exposed, and are usually inactive. Therefore, most of the researches on the catalytic performance of MOF mainly focus on the combination of MOF and nano-metal particles. There are currently six general preparation methods. Among them, the simple, easy-to-operate, and highly controllable method is to use metal particles as seeds to further grow MOF materials, so that a variety of controllable structures such as spheres, polyhedrons, and core-shell shapes can be obtained. . Various set structures can provide a powerful pore structure, and the functional groups on the ligand can also adjust the properties of electrons, thereby enriching specific gas molecules and improving catalytic activity. However, the existing problems are also very concentrated. The selected metal particles are usually precious metals, which undoubtedly increases the production cost and limits the industrial application. How to reduce production costs and promote commercial applications in the future is an urgent problem to be solved. The current method of combining theoretical calculations and experiments will be the main direction of future research.

6. Separation performance of organometallic frame

Compared with other pore structure materials, MOF materials can control the crystallinity, void regularity and surface activity of the materials through experimental design. Therefore, MOFs show great application potential in various separations, and can be applied in liquid phase and meteorology, for example: from CO2 capture, natural gas purification, H2 purification, inert gas separation, air separation to harmful gases, from From desulfurization to macromolecular inclusion, to separation of structural isomers to separation of enantiomers, various environments that require separation in gas and liquid systems. At present, MOF has been studied more maturely as a single-characteristic separation material. However, new MOFs that measure mixed gases and use column chromatography (vapor and steam) for separation still need to be explored. In addition, it is time for the large-scale industrial application of low-cost preparation of MOF materials to be tested. In the future, the application of MOF materials in separation will no longer be the selective adsorption of CO2 relative to N2 or CH4 calculated by the single-component isotherm, but will selectively capture CO2 from the hot and humid flue gas stream filled with SOx. Nitrogen oxides and other pollutants, and in the course of years of use, the material will not degrade.

7. Biological properties of organometallic framework

Compared with other carriers, the adjustable composition, structure, pore size, volume, functionalization, and flexible structure of MOF have the unique advantages of adsorbing and releasing biomolecules. The biodegradable properties of MOF materials can be changed through appropriate metal elements, joints and structures. Therefore, the degradation of MOF itself can release drugs; or the use of biologically active metals (Ag, Zn, Ca, Mn, Gd, Fe…) to introduce MOF particles with antibacterial activity or imaging properties for drug delivery. MOF materials can also be used to track the movement path of drugs in the body and analyze pharmacokinetics and drug effects. Studies have found that the particle size, film, gel and composite materials of MOF materials are the main factors affecting drug delivery; MOF nanoparticle surface modification regulates its biodistribution (biological paste, stealth, targeting, etc.), showing strong biological value ; MOF calculations found that the crystal framework makes the analysis of host-guest interactions and the encapsulation/release of model drug systems easier. However, the current research on the kinetics of drug loading, degradation mechanism and drug delivery of MOF is still scarce; there are few studies on the toxicity of MOF. The biological research of MOF materials in the future will greatly promote the development of the medical field.

8. Hydrogen storage performance of organometallic frame

The binding energy and storage capacity of MOF hydrogen storage are increasing, among which high specific surface area, vacancy coordination sites and strong surface dipole moment play a significant role. The H2 absorption of Zn4O(BDC)3 is 10% of the mass and 66 g L-1. It is expected that the weight capacity improvement of this structure will not lose the gas storage density. However, at 25°C, MOF materials require strong surface dipoles and open metal coordination sites to increase the affinity of H2 in order to improve the hydrogen storage performance of the material. The difficulty of MOF materials for hydrogen storage lies in the design of bridging ligands, surface functional groups and the selection of metal ions to form a hydrogen storage framework structure. In the future, the stability and cost of MOF materials and the industrialized hydrogen storage research for large-scale production will greatly improve the storage and use of H2.