Introduction to cationic light-curing monomers

-

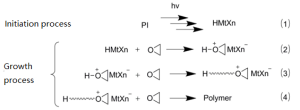

Cationic photopolymerization mechanism

- Anaerobic polymerization resistance

- Less human irritation from epoxy monomer

- Less volume shrinkage

Better performance of polymerization product

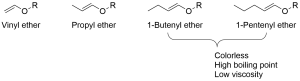

Vinyl ether monomers

-

-

Classification of vinyl ether monomers

-

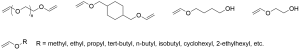

Vinyl ether-based monomers in market

Vinyl ether-based monomers in market -

Characteristics and applications of vinyl ether monomers

-

Characteristics:

- Very low viscosity

- High dilution capacity

- Low toxicity

- Very fast reaction time (comparable to acrylate monomer)

- Single structure. The stability of the product formed with vinyl ether monomer curing agent alone is poor

Application: Used as a cationic light-curing reactive diluent, not used alone

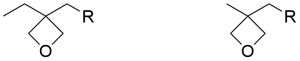

Epoxy propane monomer

-

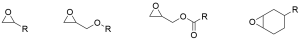

Classification of Epoxy propane monomer

-

Classification of Epoxy propane monomer -

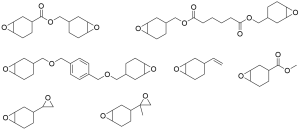

Epoxy propane monomer in market

-

Epoxy propane monomer in market -

2-(3,4-Epoxycyclohexyl)ethyltriethoxysilane CAS 10217-34-2 - 2-(3,4-Epoxycyclohexyl)ethyltriethoxysilane CAS 10217-34-2

![Bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane CAS 18724-32-8](https://www.gmchemic.com/wp-content/uploads/2022/06/Bis2-34-epoxycyclohexylethyltetramethyldisiloxane-CAS-18724-32-8-300x73.png)

Bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane CAS 18724-32-8 - Bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane CAS 18724-32-8

-

Characteristics and applications of epoxy propane monomer

Characteristics for Glycidyl ether epoxy monomer

- Longer induction period for cationic light curing

- Low cationic light-curing activity

- Unsatisfactory performance of the product

Characteristics for Alicyclic epoxy monomers

- Lower viscosity

- Fast cationic light curing speed

- Excellent performance of the product

- Less variety of products, large differences in curing activity between products

Oxetane monomers

-

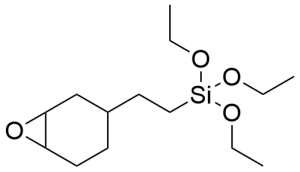

Classification of Oxetane monomers

-

Classification of Oxetane monomers -

Oxetane monomers supplied by our company

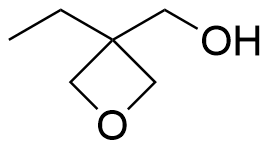

- 3-Ethyl-3-(hydroxymethyl)oxetane CAS 3047-32-3

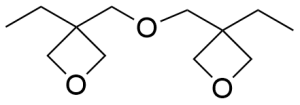

- 3,3′-(oxydimethanediyl)bis(3-ethyloxetane) CAS 18934-00-4

- 3,3′-[(1-methylethylidene)bis(4,1-phenyleneoxymethyl)] CAS 105071-04-3

![3,3′-[(1-methylethylidene)bis(4,1-phenyleneoxymethyl)] CAS 105071-04-3](https://www.gmchemic.com/wp-content/uploads/2022/06/33′-1-methylethylidenebis41-phenyleneoxymethyl-CAS-105071-04-3-300x58.png)

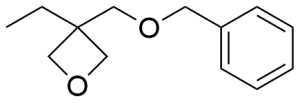

- 3-Ethyl-3-(phenylmethoxymethyl)oxetane CAS 18933-99-8

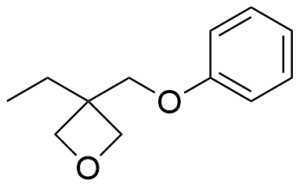

- 3-Ethyl-3-(phenoxymethyl)oxetane CAS 3897-65-2

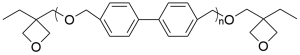

- 1,4-Bis[(3-ethyl-3-oxetanylmethoxy)methyl]benzene CAS 142627-97-2

![1,4-Bis[(3-ethyl-3-oxetanylmethoxy)methyl]benzene CAS 142627-97-2](https://www.gmchemic.com/wp-content/uploads/2022/06/14-Bis3-ethyl-3-oxetanylmethoxymethylbenzene-CAS-142627-97-2-300x65.png)

- 4,4′-Hydroxymethylbiphenyl polymer oxetane CAS 358365-48-7

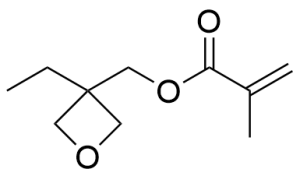

- 3-Ethyl-3-methacryloxymethyloxetane CAS 37674-57-0

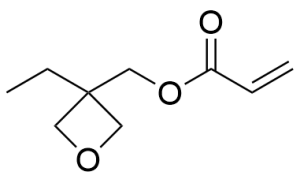

- (3-Ethyl-3-oxetanyl)methyl acrylate CAS 41988-14-1

- 3-Ethyl-3-[[3-(triethoxysilyl)propoxy]methyl]oxetane CAS 220520-33-2

![3-Ethyl-3-[[3-(triethoxysilyl)propoxy]methyl]oxetane CAS 220520-33-2](https://www.gmchemic.com/wp-content/uploads/2022/06/3-Ethyl-3-3-triethoxysilylpropoxymethyloxetane-CAS-220520-33-2-300x110.png)

Characteristics and applications of oxetane-based monomers

Characteristics:

- Low curing volume shrinkage

- Low viscosity

- Low toxicity

- Fast reaction speed

- Ability to frontline polymerization and delayed curing

- Good performance of polymerization products

-

Influencing factors of cationic light curing

- Nucleophilic/basic substances

- The effect of temperature. During curing, the higher the temperature the faster the curing speed. (pre-baking, post-baking, self-produced heat)

- Effect of water/moisture. A small amount of water speeds up the curing process, and as the water content and humidity increase, cationic curing is inhibited.

- The effect of alcohol. Chain transfer agent that speeds up cationic light curing but reduces the molecular weight of the polymer.

- The effect of viscosity. The higher the viscosity of the formulation, the slower the reaction rate.